Exploring the World of 3D Printed Car Parts

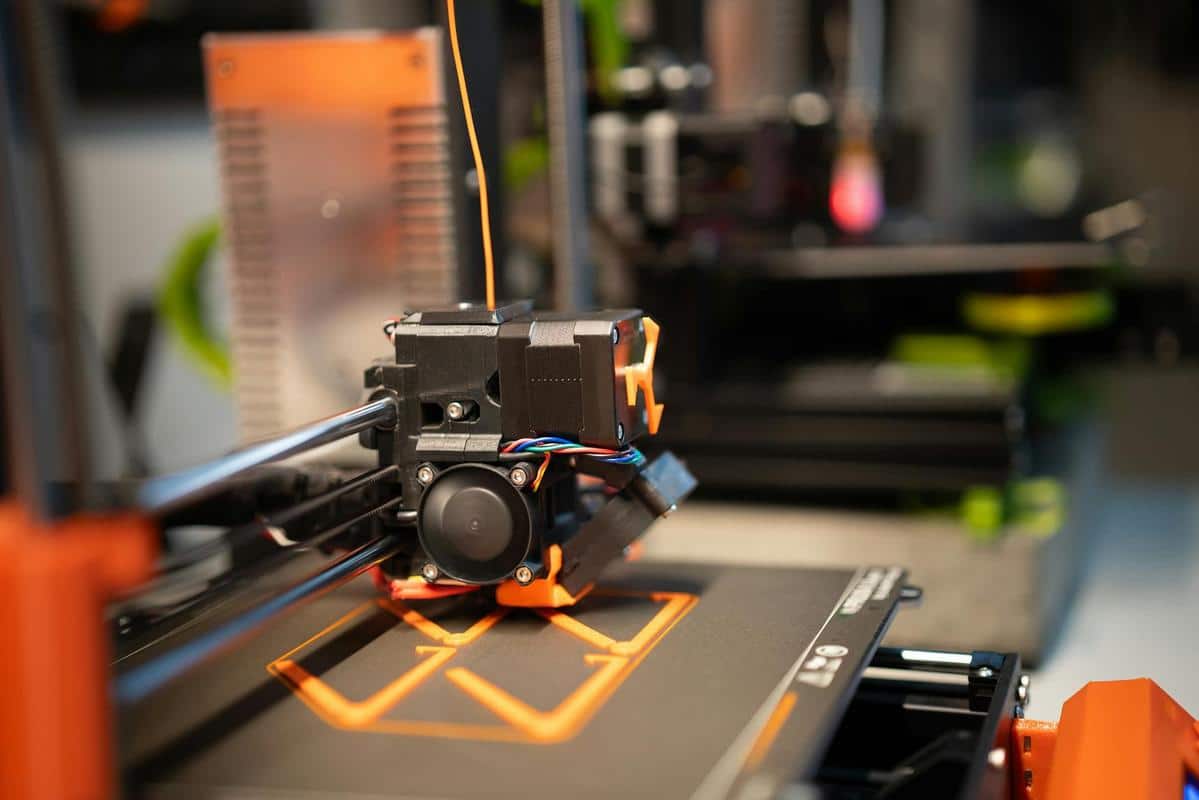

The realm of automotive innovation is ever-evolving, and one of the most intriguing advancements in recent years is the use of 3D printing technology to create car parts. This technology is reshaping how we think about vehicle design, manufacturing, and repair.

3D printing, also known as additive manufacturing, is making significant inroads in the automotive sector. By layering materials to form intricate shapes, 3D printing allows for the creation of complex car parts that were previously difficult or impossible to produce using traditional methods. This technology is not only cost-effective but also offers unparalleled customization options.

Understanding 3D Printed Car Parts

3D printed car parts can range from simple components like knobs and brackets to more complex parts such as engine components and even entire car bodies. The flexibility of 3D printing allows manufacturers to create parts that are lightweight yet strong, optimizing vehicle performance and efficiency.

Expert Insights

According to Dr. Jennifer Lewis, a pioneer in 3D printing at Harvard University, “The ability to produce parts on-demand and with less waste is transforming the automotive industry. We’re seeing a move towards more sustainable manufacturing processes.”

Notable Statistics

Research from SmarTech Analysis indicates that by 2029, the automotive 3D printing market could be worth approximately $9 billion, highlighting its growing importance in the industry.

Real-World Examples

Consider the case of a German car manufacturer that used 3D printing to produce a new intake manifold, reducing its weight by 50% and improving airflow efficiency. This is just one example of how 3D printing is enhancing vehicle performance.

Table: 3D Printed Car Parts Applications

| Application | Benefits |

|---|---|

| Prototyping | Reduces time and cost |

| Custom Parts | Allows for personalization |

| Replacement Parts | Quick and easy production |

| Lightweight Components | Improves fuel efficiency |

| Complex Geometry | Enables innovative designs |

| Tooling | Reduces manufacturing costs |

| End-Use Parts | Boosts production flexibility |

| Spare Parts | Minimizes storage needs |

Actionable Tips

- Explore 3D printing services that specialize in automotive parts for custom or hard-to-find components.

- Keep an eye on emerging materials that offer enhanced durability and performance for 3D printed car parts.

- Consider investing in a small 3D printer for prototyping if you’re involved in automotive design or repair.

When selecting materials for 3D printing car parts, always consider the environmental conditions the part will face, such as heat, pressure, and exposure to chemicals.

FAQs

What materials are used for 3D printing car parts?

Common materials include various plastics, metals like aluminum and titanium, and even carbon fiber composites.

How durable are 3D printed car parts?

3D printed parts, when made from high-quality materials, can be as durable as traditionally manufactured parts.

Is 3D printing more expensive than traditional manufacturing?

It can be more cost-effective, especially for small batches or complex parts that would be expensive to mold or machine.

Conclusion

The world of 3D printed car parts offers a glimpse into the future of automotive manufacturing, where customization, efficiency, and innovation meet. As technology advances, so too will the capabilities and applications of 3D printing in the automotive sector. Whether you’re a car enthusiast or a professional in the industry, the potential of 3D printing is something worth exploring. Embrace the possibilities and stay informed about the latest developments to leverage the full potential of this technology.